Fascination About Kubota Accessories

Metal fabrication is the production of metal structures by cutting, bending and assembling processes. It's a value-added 1 process involving the creation of machines, components, and arrangements from several raw materials.

Usually, a fabrication shop bids a job, usually based on engineering drawings, and if awarded the contract, assembles the item. Large fab stores employ a large number such as machining, cutting, forming and welding.

Just like other production procedures, both human labor and automation are widely used. A manufactured merchandise may be referred to as a fabrication, and stores are called fab shops. The end products of additional common types of metalworking, like machining, metal stamping, forging, and casting, can be similar in shape and function, but those procedures are not classified as manufacture. .

5 Easy Facts About Hay Spear For Tractor Explained

Bending is done by hammering (manual or powered) or through press brakes, tube benders and related tools. Press brakes are used by modern metal fabricators to air-bend or sheet metal sheet into form. CNC-controlled backgauges use hard stops to place trim components to place flex lines in certain positions.

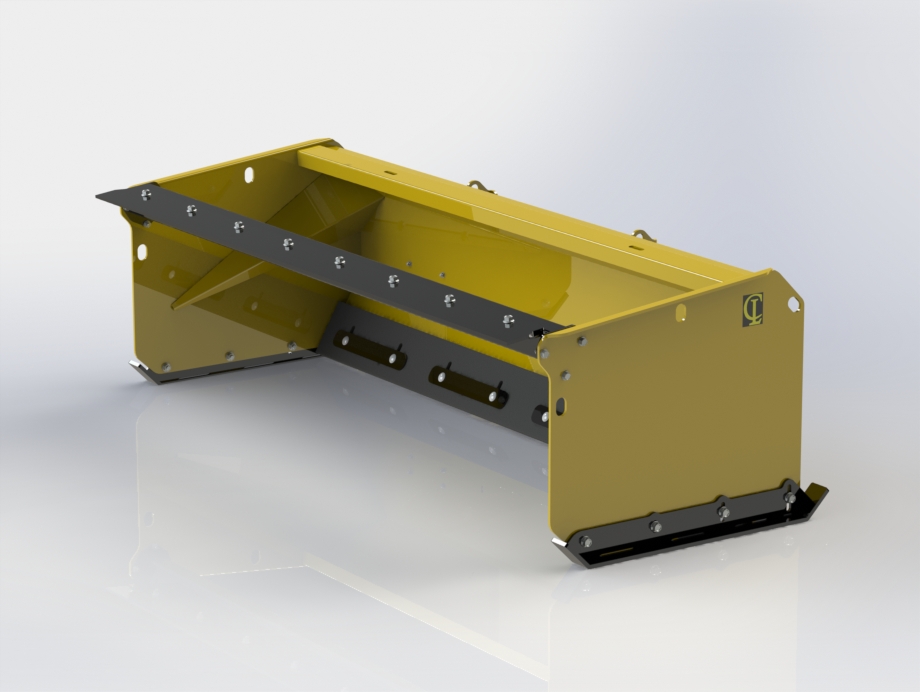

C L Fabrication

420 S 8th St, Clarinda, IA 51632, USA

(712) 542-5500

Assembling (joining of bits ) is done by welding, binding together with adhesives, riveting, threaded fasteners, or additional bending in the kind of crimped seams. Structural steel and sheet steel will be the usual materials for fabrication; welding wire, top and/or fasteners are used to join the cut bits.

Fabrication shops and machine shops have overlapping capacities, however, manufacturing stores generally concentrate on metal preparation and assembly (as described fabrication work details previously ). Machine shops cut metal, but focus primarily on the machining of components on machine tools. Some companies do machining and fab function.

Ironworkers, also known as steel erectors take part in manufacture. They work with sections, produced in fab stores, that are sent to the website.

Get This Report about Jcb Attachments

Particular ring saws for cutting alloy have hardened blades and feed mechanics for cutting. Abrasive cut-off gears, also known as chop sawsare similar to miter saws but possess a steel-cutting abrasive discs. Large pieces of steel can cut on with little effort.

Burn tables are CNC (computer-operated) cutting torches( generally powered by gas. Plasma and laser cutting tables, and water jet cuttersare also common. Steel is filled on the desk as well as the parts are cut out as engineered. The support table consists of a grid.

In manufacture of structural steel metal fabrication jobs in missouri by laser and plasma cutting, robots move on the cutting head in three dimensions around the cut material. .

Forming converts flat sheet metal into 3-D parts 4 by employing pressure without adding or removing material. 5 The power has to be great enough to change the initial shape of the metal. Forming could be controlled together with resources such as dies and punches. Machinery can modulate direction and force magnitude. Machine-based forming can unite forming and welding to produce lengths of fabricated sheeting (e.g.

Application and Appropriate design of resources with machines produces a repeatable form that may be utilized to create products for several industries, such as jewellery, aerospace, automotive, building, architectural and civic.

Some Known Questions About Hay Spear For Tractor.

Machining is a trade of eliminating stainless steel custom fabricators inc material to ensure it is a shape. Fab stores have some machining capacity, using metal lathes, millsand drills, and other machining tools.

Welding is the main focus of steel fabrication. Formed and machined parts are constructed and tack-welded in place. If weldments have been arranged, a fixture may be utilized to locate parts for welding. A welder then finishes the job based on engineering drawings (for comprehensive welding) or with their own expertise and judgement (if no information are provided). .

Measures may be necessary correct or to check warping of weldments because of heat. These may consist of redesigning the piece to require welding, using staggered welding, using a fixture, covering the weldment in sand because it cools, and post-weld straightening.

Straightening of steel weldments is done by having an oxyacetylene torch. In this highly specialized work, warmth is applied to the steel in a slow sweep, because it cools causing the steel to contract at the way of the sweep. An extremely skilled welder can eliminate significant warpage this way. .